The STEIN-Kugelventil GmbH was established in Lauingen/Germany at June 7th 1988 by Günter Stein.

A patented invention made it possible for the first time to produce valves with special recesses in the valve element (spherical segment). Many patented inventions followed until today`s spherical segment valve with hydraulic cushion and capsuled spring

Through the years, the STEIN-Kugelventil GmbH has developed into one of the leading valve manufacturers in the field of micro hydraulics. The valves in cartridge design convince worldwide in different systems with their:

- excellent closeness

- low pressure drop

- compact design

- high load carrying capacity

- reliable hydraulic cushion

- reduced turbulent flow

- insensitivity to dynamical acceleration

- long lifecycle

- simplicity to assemble

The STEIN-Kugelventil GmbH is now managed by the third generation. The objective is still defined clearly. The products should set standards with a consistent further development, process optimization and the resulting outstanding quality.

Daily optimization creates sustainability in the quality of our products.

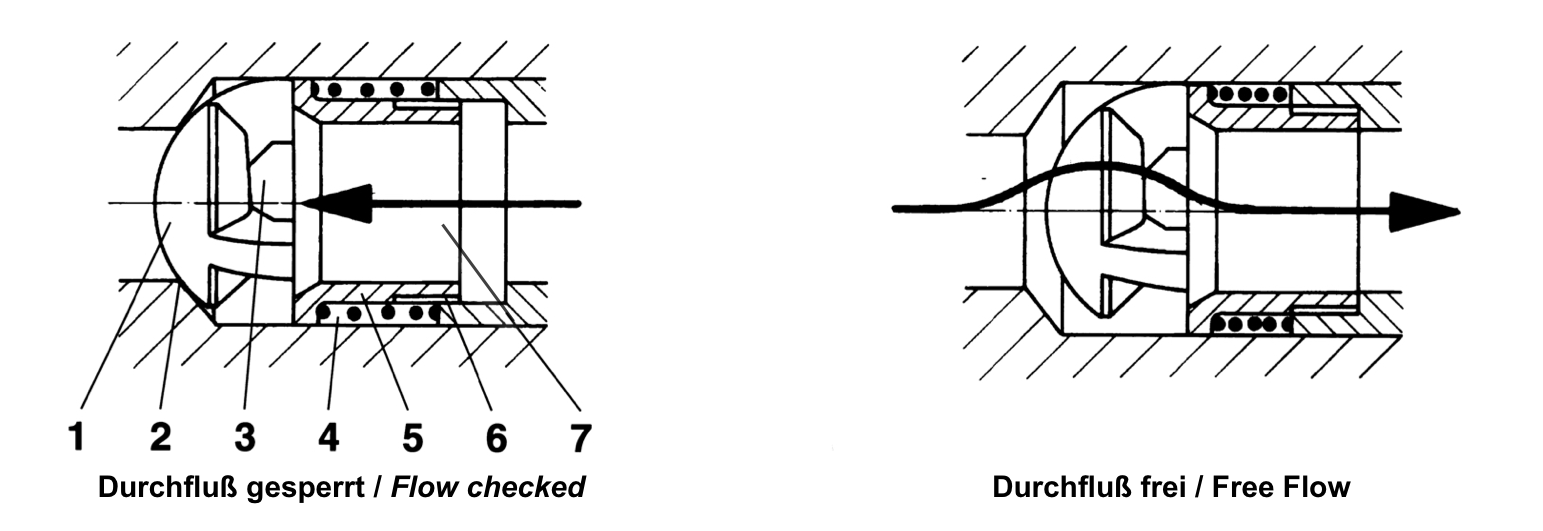

Basic principle of a STEIN ball valve with a moveable spherical segment and axial laminar flow.

(Abstracted from sales documents of 1988)

The used spherical segments of diameters up to 12 mm are made of hardened, ground and polished steel balls. The moving spherical segment (1) seals with its surface at the valve seat (2) and is inserted radially, guided with almost no backlash, into the housing.

The recesses (3) in the valve element enable flow with minimum pressure drop and turbulence, which is even improved by the means of no valve parts being behind the valve element in the flow chamber (7).

The spherical segment is guided with the help of a guide sleeve (5) which rests on the contact slots. The closing spring (4) of the valve is located behind the guide sleeve. In this way, the flow chamber of the valve is completely free. In addition, the guide sleeve has longitudinal grooves (6) on its entire circumference, so that these longitudinal grooves act as control edges in the flow direction with the opening movement of the spherical segment. They are overlapped and enclosed on the spring impact ring, which provides impact damping in the flow direction.

Up to a maximum spherical segment of diameters up to 12 mm, the cartridge check valves are designed with a separate guide sleeve, while the larger valves with a spherical segment diameter over 15 mm are manufactured in one piece. This ingenious design results in high operational reliability, even in highly dynamic applications (e.g., in accumulator operation).

The perspective drawing demonstrates the structure of a valve. The valves are depending on their size designed for a maximum flow of 80 l/min. At valves with radial outflow (e.g. pressure relief valves) spherical segments without recesses (3) are used.